Stocking up on PPE

Photo courtesy of Bill Eley

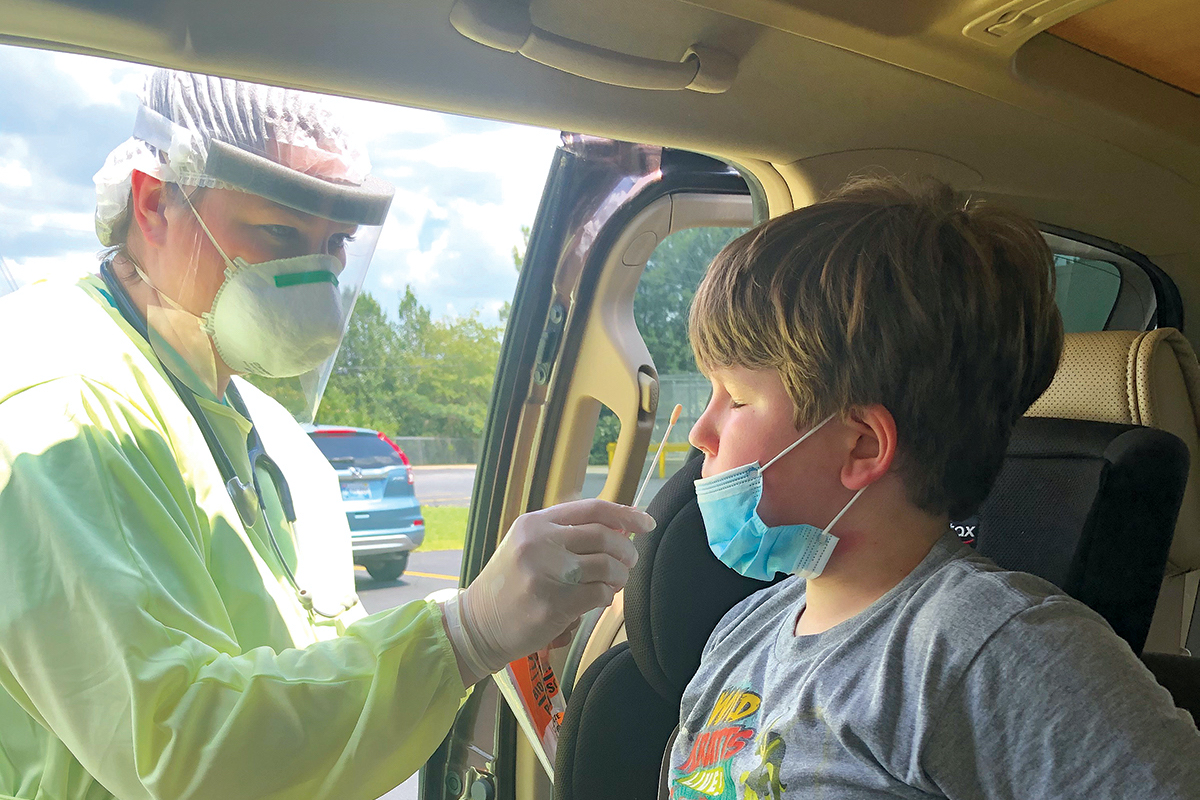

A huge challenge during the pandemic for hospitals around the world has been keeping a constant supply of personal protective equipment (PPE), such as medical-grade masks, gloves, and gowns, in stock for health care workers.

As demand intensified, Emory Healthcare used multiple supply chains from around the world, as well as local distributors and manufacturers, to stabilize its supply. It also opened a drive-through community donation center on the Emory campus for PPE in March.

“We have been ordering from other countries—Mexico, Central America, Vietnam, and other Southeast Asian countries as well,” says Lee Partridge, director of Supply Management at Emory Healthcare.

Emory secured a robust stock of PPE in the form of masks, gloves, and sanitary wipes, numbering in the hundreds of thousands. A significant portion of these donations came from China.

For example, Global Emory Scholars in China, a group of former School of Medicine trainees who returned home after their training, donated more than 6,000 masks purchased through a fundraising effort called Love Emory (see photo, above).

Although constant restocking is required, PPE supply chains have normalized a bit after the initial surges.

“We have focused on sourcing from American manufacturers as much as possible,” Partridge says. “This has eliminated long lead times and has made the supply chain more secure.”

By purchasing from these manufacturers in bulk and opening a warehouse for future needs, Emory Healthcare is now stable with most required protective garb.

Partridge says Emory Healthcare will continue seeking reliable sources that can provide the requested supplies. These protective products are more valuable than ever as the coronavirus makes a resurgence in different areas around the country.

Preserving multiple supply chains is key to ensuring that medical professionals remain safe when treating patients with COVID-19, he says.

Medical teams have also been charged with making their PPE last longer, by disinfecting and reusing their personal supplies. The Centers for Disease Control and Prevention (CDC) provides guidelines so that doctors and nurses can extend their use of protective gear such as N95 respirator masks and face shields.

According to Kari Love, program director of infection prevention at Emory Healthcare, one of the ways this equipment is being conserved is through an Emergency Use Authorization for reprocessing N95 respirators.

“The reprocessing includes sending the N95 to the sterile processing department where they placed the masks in sterilizers that we also use for surgical instruments,” says Love. “Once the mask has gone through the process, it is returned to its owner.”

Under normal conditions, hospital staff would dispose of the masks after initial use, but those practices needed adjustment as the virus continued to spread.

The CDC also recommends eye protection when treating patients with COVID-19, so rather than throw away these face shields, Emory Healthcare workers disinfect their shields.

“Our supply chain team has also sourced a variety of different types of eye protection, including face shields and goggles,” Love says. “Georgia Tech also worked with us to create a face shield that has a headband that is sturdy enough to be reused.”